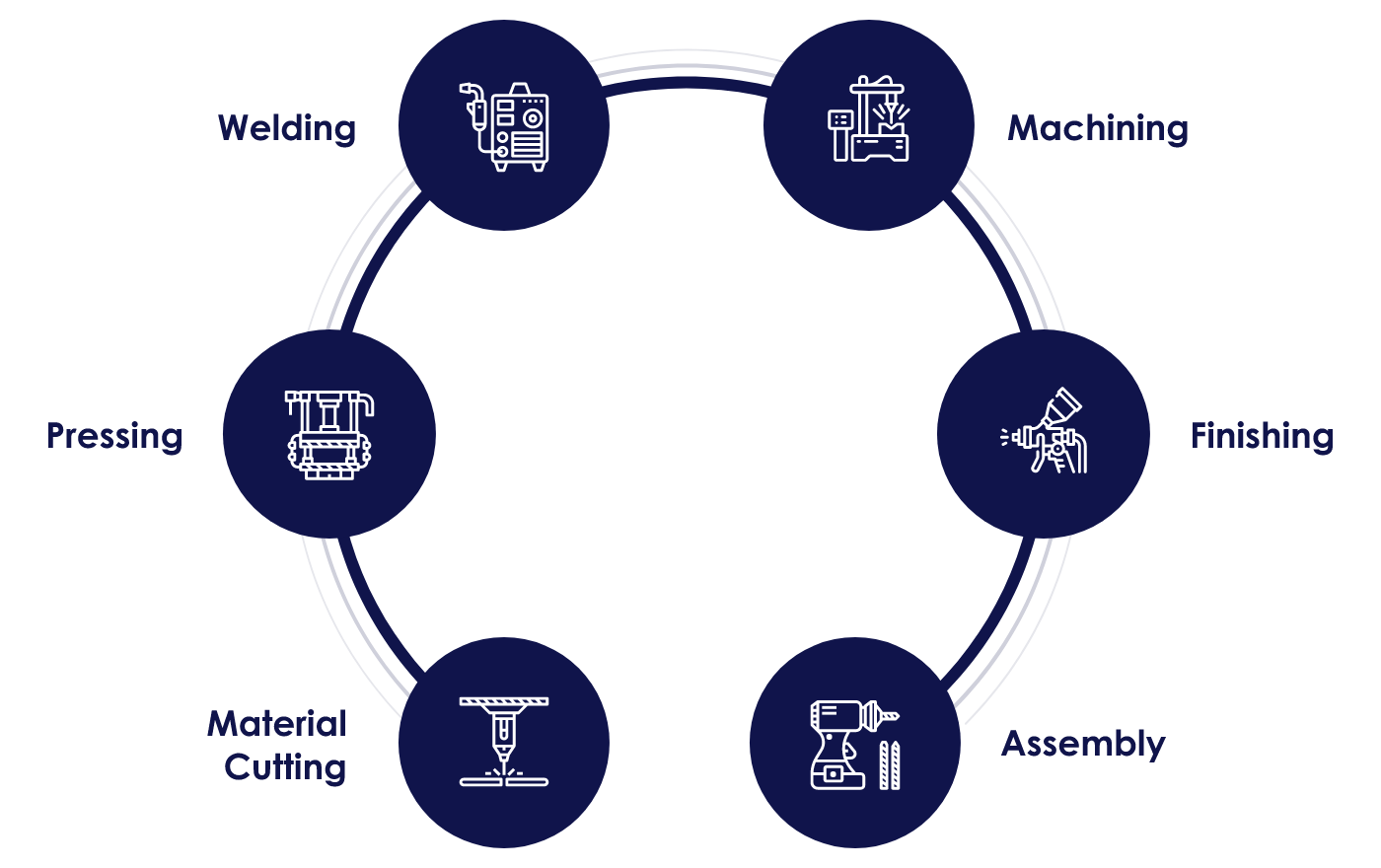

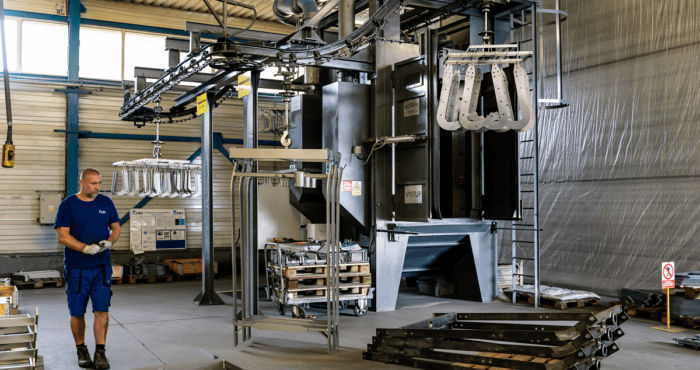

Design and Production of Jigs, Production of Samples and Prototypes

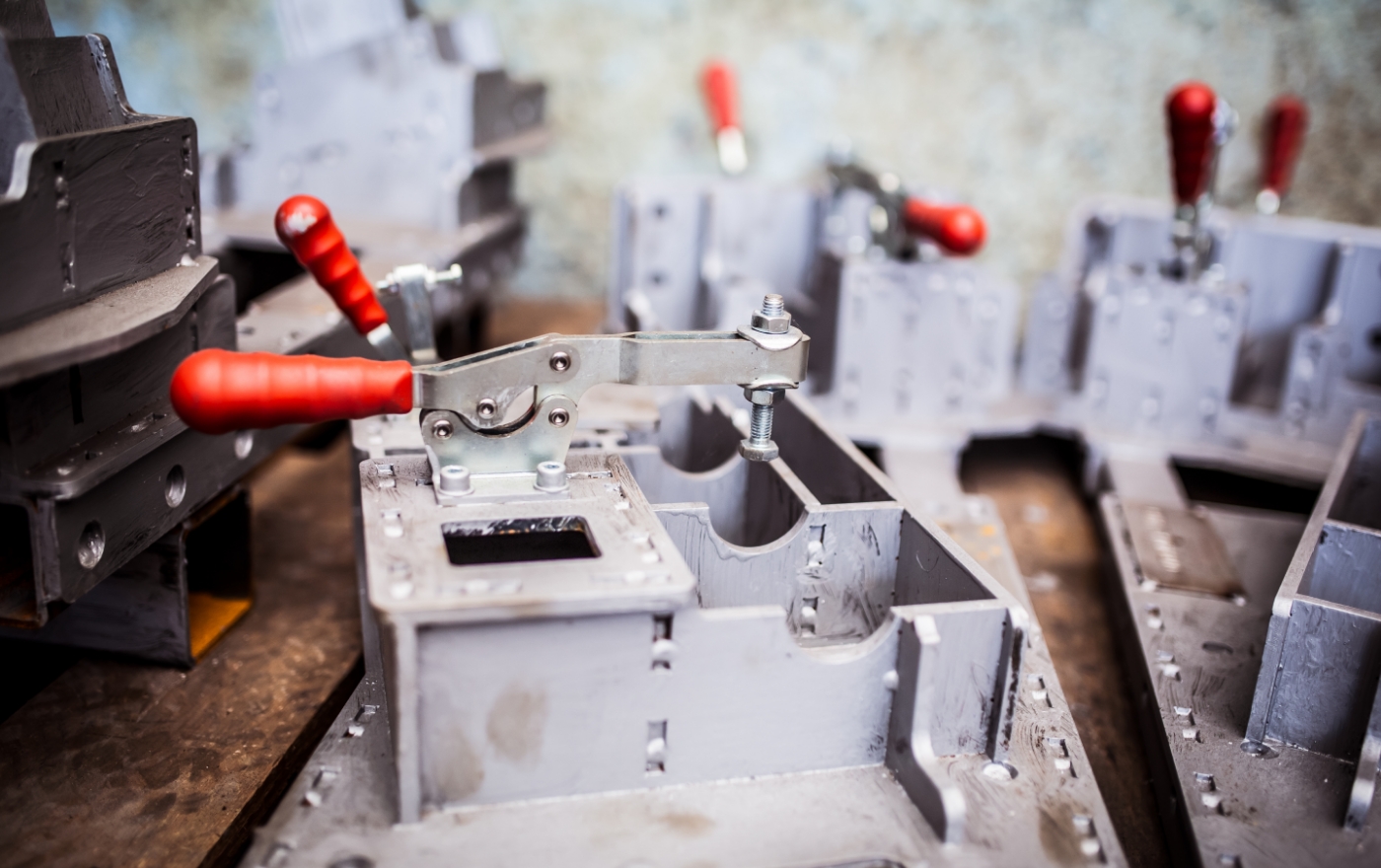

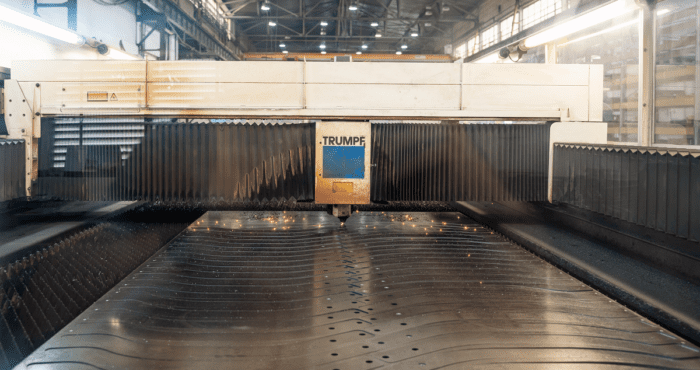

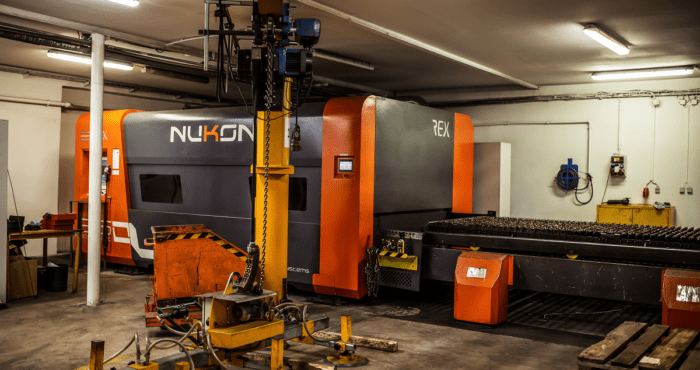

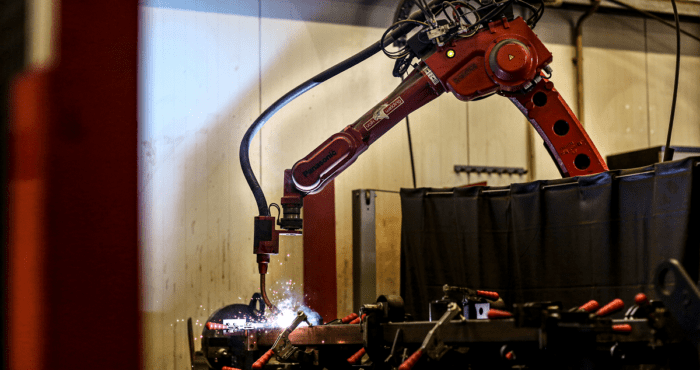

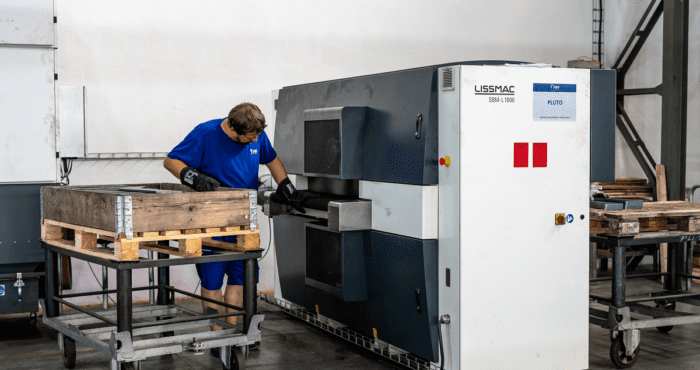

New cooperation with us always starts with sending your drawing documentation and subsequent production of samples, which we are able to deliver within a matter of weeks (about 8-12 weeks). During the implementation of a new project, we proactively consult with the customer on all details and participate in the optimal production process, e.g. by designing and manufacturing our own welding jigs and fixtures.

A customer audit or a visit to the customer’s production site is also standard. After successful sampling, we put the project into mass production. We are currently producing batches of up to 150 prefabricated welded sub-assemblies per week for some projects.